Alright so, I managed to have one of my big table free of rubbish over the week end !

And I also had the right to spend 1 hr into the workshop !

It's Christmas !!

Here we go...

Starting with the wings for once...

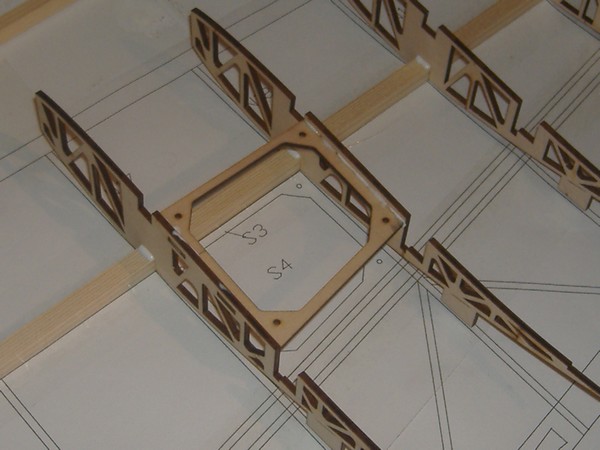

The ribs and various parts are lay on the plan..

The profile is a MS535... All the ribs are made of 3mm plywood. Spars are 8x8mm pine from the local hardware shop.

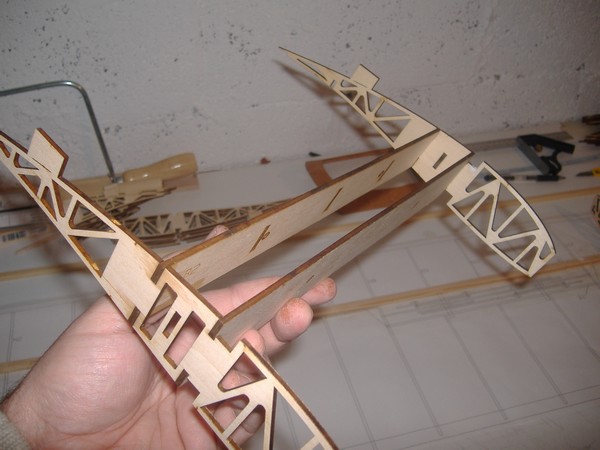

First job, is to cut the end of the spars to fit in the root rib.

What's need to be cut :

And the fit...

After that, it's just a question of gluing the ribs to the spar...A few bits are glued during the process, like the aileron servo frame :

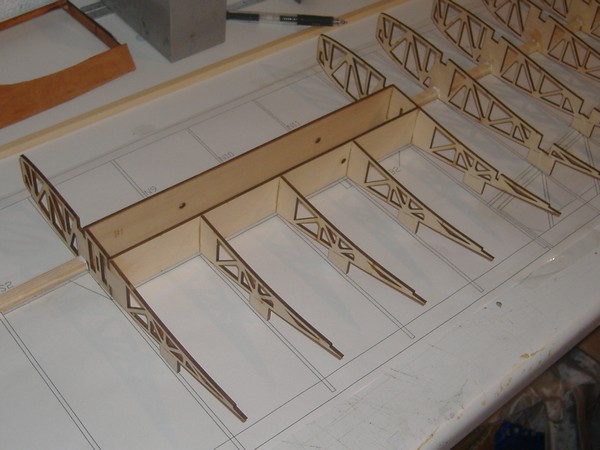

And the big part of the wings, the airbrakes box/frame.

All the parts are glued together "in the air", all the parts slotting together to have all that done accurately...

And the box is then glued on the spar, and the rear end of the ribs, glued to the box...

And we can glue the rest of the ribs... Always check for perpendicularity during the entire process !

And finally, the top spar is glued.

Everything is set for drying overnight with a few weights there and there...

Results tonight !

And that was the end of my hour !

Tonight, plan is to glue the TE and the aileron frame. And I will have a look at the airbrakes system ! Works in theory, but in practice, that can be another story !