Kitchen table is a no-go zone for the good lady of the house who is surprisingly encouraging..

Oh, don't worry ,...that wont last long

Well, if none of the other old farts who normally contribute to this forum are going to answer you David, you’ll have to put up with my tupence worth.

From purely personal experience I’d say…………

Epoxy glue has the advantage of forming a very strong bond, when it’s been mixed properly. A lot of epoxies come is paste form. Araldite is one such brand. When mixing these type of glue it’s important to make sure that all of the hardner has come into contact with all of the glue. I find this is best done by using a sort of “squashing” motion and to mix the two parts for at least one minute before attempting to use the glue on a joint.

Anyway as far as gluing ability,… good quality epoxies form very strong, although generally rather ‘hard’ bonds with little or no ‘give‘. This type of glue is also a bit on the heavy side when used in large amounts compared to the other two types you mentioned.

Cyanoacrylate glues, (CA, or ‘super’ glues) also come in different qualities. Particularly when used in conjunction with an activator they make for extremely fast assembly of model planes. That’s their plus side. The downside, in my experience, is that although thin CA tends to ’wicker’ into the wood to obtain a very good grip, the joint itself has a tendency to be rather brittle. The other downside is that I found it’s very easy to end up using a lot of this type of glue on models, probably because it wickers into the wood and doesn’t look like there is enough glue at the joint to do the job, thereby using a lot of the glue which costs more money and adds weight of the model.

PVA or ‘White’ wood glue. This is a good all round wood glue. It tends to take about thirty minutes to an hour to set, preferably leave it for a couple of hours before stressing it. This type of glue also allows a little bit of ‘give’ when the joint is placed under stress.

So, of these three types what do you use? You asked about glues for the fuselage. I’d suggest it depends of the design of the fuse. If it’s a ‘built up’ fuse,( In the same way as the wings are Built Up on your model,) with longerons being held in position with formers at various points down the fuse, then probably CA would do the job fine.

If the sides of the fuse are made of sheet lite-ply then I’d use PVA to secure the longerons in place, as this will be a long continual joint.

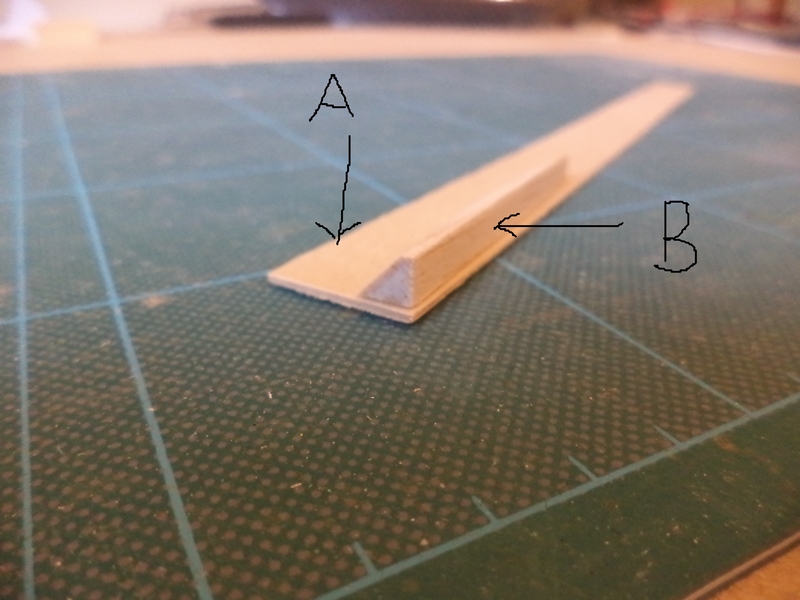

(See picture)

A = Lite ply ( Used for the sides of the Fuse on some models)

B = Triangular section longeron, used to stiffen the side of the Lite-Ply fuselage.

So what do you think of that David?…….David? DAVID! Wake up!!