No matter how hard you try to think of every potential problem when modifying a plane from it’s standard construction, there always seems to be one or two aspects that ‘get through’ the mind searching that goes on before actually starting the project.

At the moment I’m trying to build, what is otherwise, a standard SIG Riser 100. The recommended weight, according to the manufacturer, is 45 to 49ozs. I’m trying to trim about 10% - 15% off of that to have it flying at around 40ozs.

As a two channel, (well three if you include the spoilers) polyhedral floater I figured that it shouldn’t be too hard to, a) build, and b) modify from standard construction.

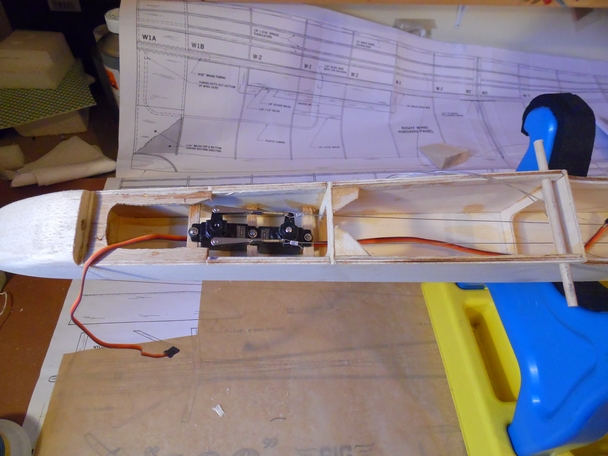

As I’ve mentioned elsewhere on this forum, by replacing nylon push rods for closed loop cables, a steel wing joiner for carbon rod and other judicial shaving and drilling of airframe components, especially around the tail area, I’m hopeful of achieving my goal without weakening the plane to the point of catastrophic brakeage during use. Moving the servos further forward than specified in the plans should help to balance the plane with less lead in the nose. I’ve even limited myself to using no more than a pre-assessed amount of glue so as not to go over the weight limit I’ve set myself.

( I just hope this plane doesn’t fall apart on first landing! :cry: )

Of course by replacing some of the supplied items the total cost has gone way over the cost of building this model in standard form. A fact that has just come home to me having received my credit card statement this morning :shock: . Indeed for the gains that I hope to make by all this additional work, the additional cost has made it totally unviable financially. But what is life without a challenge? So I’m plodding on. Solving problems that I hadn’t foreseen as they arise, whilst hoping I’m not creating further difficulties for myself later in the build.

At the moment I’m pondering on a closing mechanism for the spoilers. :?: The manufacturer supplied two 5gram weights to stick to the underside of each spoiler to keep them down during flight. That’s 10grams in total. So they‘ve gone in the bin! :evil:

Another problem is that despite all my best efforts, it turns out that one wing half is heavier than the other, :!: …….by 15grms at the wing tip! Drilling one of the wing tip blocks has saved 5grm. Don’t know how I’m going to remove the remaining 10grm though. :?:

I’ve long given up on the idea that the fruits of all my labours will produce a good looking model. With cables coming out of the fuse all over the place, and holes where there weren’t supposed to be, covering this model is going to be challenge in itself. But I guess that’s the nature of the project. Solving problems.

I’m confident this bird will fly. I only wonder how well she’ll fly and if she’ll stay together on landing. Whatever the outcome of this build, it’ll be an “

interesting” maiden flight.

I’ll keep ya’all posted

Wish me Luck,

Keith (little version)